Round Pin Shackles

Round Pin Shackles can be used in tie down,towing, suspension or lifting applications where

the load is strictly applied in-line. Round pin shackles should never be used in rigging

applications to gather multiple sling legs, or where side loading conditions may occur.

the load is strictly applied in-line. Round pin shackles should never be used in rigging

applications to gather multiple sling legs, or where side loading conditions may occur.

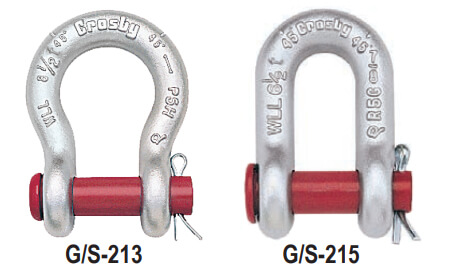

Screw Pin Shackles

Screw Pin Shackles are used in Pick and Place* applications.

For permanent or long-term installations, Crosby recommends the use of bolt type shackles.

If you choose to disregard Crosby’s recommendation, the screw pin shall be secured from rotation or loosening.

Screw pin shackles can be used for applications involving side-loading circumstances.

Reduced working load limits are required for side-loading applications.

While in service, do not allow the screw pin to be rotated by a live line, such as a choker application.

* Pick and Place application: Pick (move) a load and place as required.

Tighten screw pin before each pick.

For permanent or long-term installations, Crosby recommends the use of bolt type shackles.

If you choose to disregard Crosby’s recommendation, the screw pin shall be secured from rotation or loosening.

Screw pin shackles can be used for applications involving side-loading circumstances.

Reduced working load limits are required for side-loading applications.

While in service, do not allow the screw pin to be rotated by a live line, such as a choker application.

* Pick and Place application: Pick (move) a load and place as required.

Tighten screw pin before each pick.

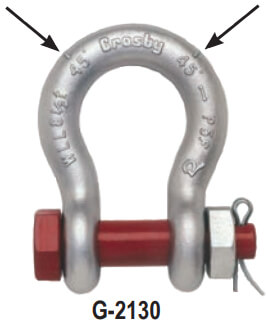

Bolt-Type Shackles

Bolt-Type Shackles can be used in any application where round pin or screw pin shackles are used.

In addition, they are recommended for permanent or long term installations and where the load may slide on the shackle pin causing the pin to rotate.

The bolt-type shackle’s secondary securement system, utilizing a nut and cotter, eliminates the requirement to tighten pin before each lift or movement of load.

In addition, they are recommended for permanent or long term installations and where the load may slide on the shackle pin causing the pin to rotate.

The bolt-type shackle’s secondary securement system, utilizing a nut and cotter, eliminates the requirement to tighten pin before each lift or movement of load.

Crosby Quick Check

All Crosby Shackles, with the exception of 2160, 2169, 2170, 252 and 253 styles incorporate markings forged into the product that address an easy to use QUIC-CHECK® feature.

Angle indicators are forged into the shackle bow at 45 degree** angles from vertical. These are utilized on screw pin and bolt type shackles to quickly check the approximate angle of a two-legged hitch,

or quickly check the angle of a single leg hitch when the shackle pin is secured and the pull of the load is off vertical (side loaded),

thus requiring a reduction in the working load limit of the shackle.

** Round Pin Shackles utilize the 45 degree QUIC-CHECK® indicators to ensure load is applied strictly in-line.

Angle indicators are forged into the shackle bow at 45 degree** angles from vertical. These are utilized on screw pin and bolt type shackles to quickly check the approximate angle of a two-legged hitch,

or quickly check the angle of a single leg hitch when the shackle pin is secured and the pull of the load is off vertical (side loaded),

thus requiring a reduction in the working load limit of the shackle.

** Round Pin Shackles utilize the 45 degree QUIC-CHECK® indicators to ensure load is applied strictly in-line.