Point Loading of Crosby Shackles

It has been determined that all Crosby® shackles can be point-to-point loaded to the Working Load Limit without bending of the pin/bolt.

This loading can be bow-to-bow, bow-to-pin, or pin-to-pin (if there is not interference between the diameter of the shackle ears).

However, caution should be given to maintain the load at the center of the span by spacers so the load will not slide over to one side,

and overload that ear.

See “Off Center Loading Of Crosby® Screw Pin & Bolt

This loading can be bow-to-bow, bow-to-pin, or pin-to-pin (if there is not interference between the diameter of the shackle ears).

However, caution should be given to maintain the load at the center of the span by spacers so the load will not slide over to one side,

and overload that ear.

See “Off Center Loading Of Crosby® Screw Pin & Bolt

Type Shackles – 3/16” to 3” Sizes”

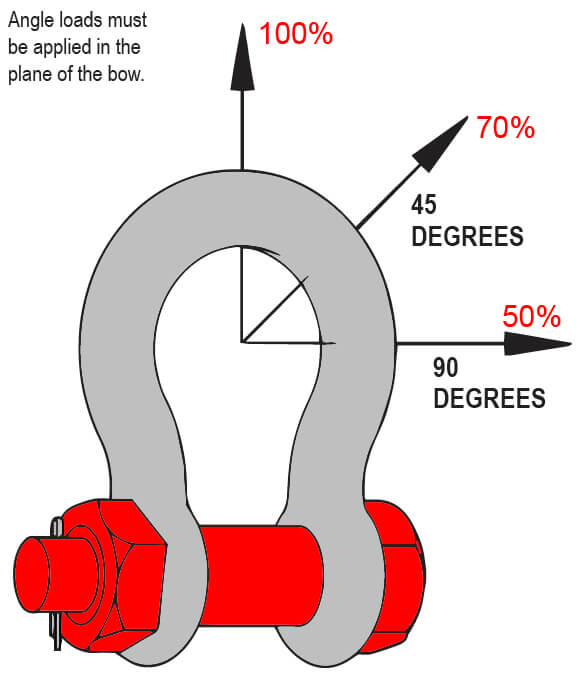

Angular Loading Of Crosby Screw Pin & Bolt Type Shackles Crosby® has made representative tests with smaller size shackles with the load applied at 90 degrees to the normal plane of loading (ie. in-line).

The test results indicated that in order to maintain a proof load of 2 times the Working Load Limit (2 x WLL), the Working Load Limit should be reduced to 50% (ie. one-half the

catalog working load rating).

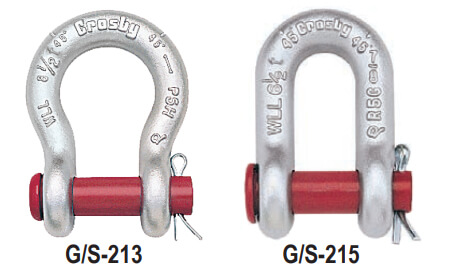

DO NOT SIDE LOAD G/S-213 OR G/S-215 ROUND PIN SHACKLES.

Calculations based on the above test indicates the Working Load Limit should be reduced as shown below for loads applied at various angles to the normal plane of loading:

The test results indicated that in order to maintain a proof load of 2 times the Working Load Limit (2 x WLL), the Working Load Limit should be reduced to 50% (ie. one-half the

catalog working load rating).

DO NOT SIDE LOAD G/S-213 OR G/S-215 ROUND PIN SHACKLES.

Calculations based on the above test indicates the Working Load Limit should be reduced as shown below for loads applied at various angles to the normal plane of loading:

| Table 1 | |

| Side Loading Reduction Chart for Screw Pin and Bolt Type Shackles Only+ | |

| Angle of Side Load From Vertical In-Line of Shackle | Adjusted Working Load Limit |

| 0° – 10° In-Line | 0% of Rated Working Load Limit |

| 11°- 20° from In-Line* | 15% of Rated Working Load Limit |

| 21°- 30° from In-Line* | 25% of Rated Working Load Limit |

| 31°- 45° from In-Line* | 30% of Rated Working Load Limit |

| 46°- 55° from In-Line* | 40% of Rated Working Load Limit |

| 56°- 70° from In-Line* | 45% of Rated Working Load Limit |

| 71°- 90° from In-Line* | 50% of Rated Working Load Limit |

+ In-Line load is applied perpendicular to pin. * DO NOT SIDE LOAD ROUND PIN SHACKLE.

| Table 1 | |

| SHACKLE SIZE GREATER THAN 3” ANGLE FROM IN-LINE (DEGREES) REDUCTION IN WLL | |

| 0° – 5° In-Line* | 0% of Rated Working Load Limit |

| 6°- 10° from In-Line* | 15% of Rated Working Load Limit |

| >10° from In-Line* | ANALYSIS REQ’D. |

For shackles larger than 125 metric tons, where the angle of the side load is greater than 5 degrees,

contact Crosby Engineering.

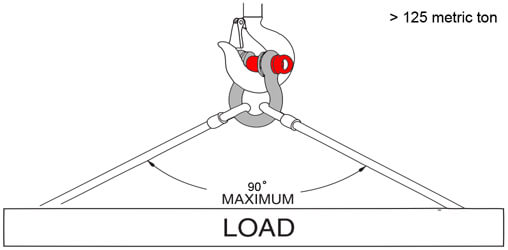

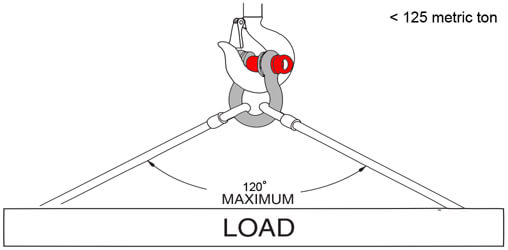

Included Angle - Shackles

Never exceed 120° included angle.

Use Bolt Type and Screw Pin Shackles ONLY.

Shackles symmetrically loaded with two leg slings having a maximum included angle of 120° can be utilized to full Working Load Limit.

For shackles larger than 125 metric tons, the maximum included angle is 90 degrees for full working load limit.

Contact our office if included angle is greater than 90 degrees.

Round Pin Shackles

Round Pin Shackles can be used in tie down,towing, suspension or lifting applications where the load is strictly applied in-line.

Round pin shackles should never be used in rigging applications to gather multiple sling legs, or where side loading conditions may occur.

Round pin shackles should never be used in rigging applications to gather multiple sling legs, or where side loading conditions may occur.

Screw Pin Shackles

Screw Pin Shackles are used in Pick and Place* applications.

For permanent or long-term installations, Crosby recommends the use of bolt type shackles.

If you choose to disregard Crosby’s recommendation, the screw pin shall be secured from rotation or loosening.

Screw pin shackles can be used for applications involving side-loading circumstances.

Reduced working load limits are required for side-loading applications.

While in service, do not allow the screw pin to be rotated by a live line, such as a choker application.

* Pick and Place application: Pick (move) a load and place as required.

Tighten screw pin before each pick.

For permanent or long-term installations, Crosby recommends the use of bolt type shackles.

If you choose to disregard Crosby’s recommendation, the screw pin shall be secured from rotation or loosening.

Screw pin shackles can be used for applications involving side-loading circumstances.

Reduced working load limits are required for side-loading applications.

While in service, do not allow the screw pin to be rotated by a live line, such as a choker application.

* Pick and Place application: Pick (move) a load and place as required.

Tighten screw pin before each pick.

Bolt-Type Shackles

Bolt-Type Shackles can be used in any application where round pin or screw pin shackles are used.

In addition, they are recommended for permanent or long term installations and where the load may slide on the shackle pin causing the pin to rotate.

The bolt-type shackle’s secondary securement system, utilizing a nut and cotter, eliminates the requirement to tighten pin before each lift or movement of load.

In addition, they are recommended for permanent or long term installations and where the load may slide on the shackle pin causing the pin to rotate.

The bolt-type shackle’s secondary securement system, utilizing a nut and cotter, eliminates the requirement to tighten pin before each lift or movement of load.

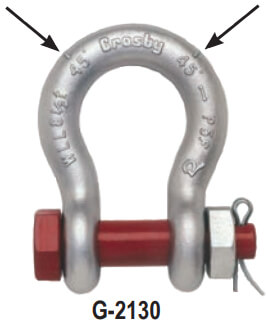

Crosby Quick Check

All Crosby Shackles, with the exception of 2160, 2169, 2170, 252 and 253 styles incorporate markings forged into the product that address an easy to use QUIC-CHECK® feature.

Angle indicators are forged into the shackle bow at 45 degree** angles from vertical. These are utilized on screw pin and bolt type shackles to quickly check the approximate angle of a two-legged hitch,

or quickly check the angle of a single leg hitch when the shackle pin is secured and the pull of the load is off vertical (side loaded),

thus requiring a reduction in the working load limit of the shackle.

** Round Pin Shackles utilize the 45 degree QUIC-CHECK® indicators to ensure load is applied strictly in-line.

Angle indicators are forged into the shackle bow at 45 degree** angles from vertical. These are utilized on screw pin and bolt type shackles to quickly check the approximate angle of a two-legged hitch,

or quickly check the angle of a single leg hitch when the shackle pin is secured and the pull of the load is off vertical (side loaded),

thus requiring a reduction in the working load limit of the shackle.

** Round Pin Shackles utilize the 45 degree QUIC-CHECK® indicators to ensure load is applied strictly in-line.