Wire ropes deteriorate during operation and need inspection throughout their service life for safety of personnel and operations, economic and safe extension of rope life, and satisfying regulatory agency requirements.

Our Wire Rope inspectors are able to carry out inspections by means of Magnetic Reflux Testing combined with a Visual Inspection. A standard visual inspection is also possible, all inspections according to the ISO 4309:2017. After completion a Inspection report for each inspected wire rope is made, including inspection data, photographs and order information for traceability.

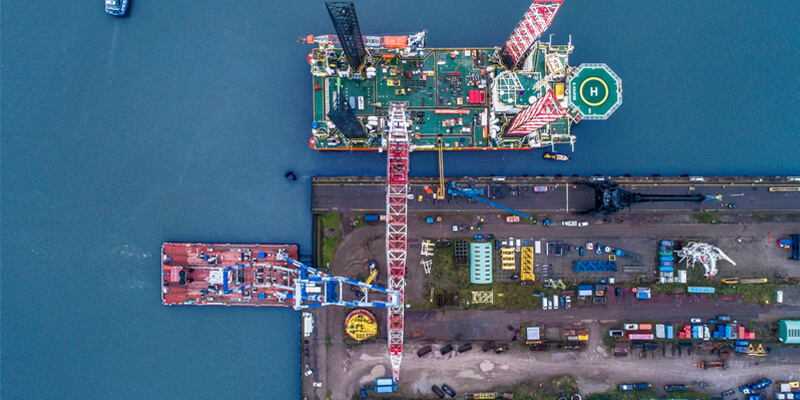

With our own fleet of spooling winches we are a flexible and independent partner, our portfolio include the largest heavy lifting cranes the world.

Meeting high quality and safety standards set by our clients in the Oil & Gas industry we strive to deliver the best service possible. We do this together with your people and other contractors where applicable, putting an emphasis on safety and awareness.

We have several options available for greasing of crane wire ropes. Contact our office to receive a quotation tailored to your needs.

Options can include greasing by hand, spraying or with a pressure lubricator.

Traditional craftsmanship combined with modern tools, splicing of steel wire ropes, and years of experience to provide the best service possible.

We change out and maintain Ski Lift wire ropes for several Indoor Ski resorts located in the Netherlands.

Our service technicians are trained, experienced and certified by DNV-GL for socket pouring with resin.

Euro Rope Netherlands uses Wirelock® resin for all sockets and standard procedures to ensure a high quality pouring.

Utilising our own fleet of spooling winches capable of handling up to 300t Reelweight we are a flexible and independent partner for spooling of umbilical wires.

Utilising our own fleet of spooling winches capable of handling up to 300t Reelweight we are a flexible and independent partner for spooling of anchor wires.

Euro Rope Netherlands has the experience and expertise required for (extensive) overhauls of crane blocks, sheaves, bearings.

Including repainting, dimension verification, repairs and Non Destructive Testing.

By means of pontoon, waterbags or solid test weights, from provision crane to Heavy Lift Cranes.

We have the knowledge, expertise and experience to deliver within the set time and budget.

Contact our office for more information and to recieve a free quotation.

Using special waterbags we can provide a cost effective solution to load test your gangway.

When required we can also provide all hoses and pumps required.

Our service technicians have a wide variety of equipment available, contact us to receive a quotation tailored to your needs.

The in house testbed at our Workshop location is certified by NMI.

We carry out Destructive and Non-Destructive test according to our clients’ needs.

With our own fleet of calibrated and certified load links, load shackles and rigging equipment we can assist you with bollard pull testing.

Annual Inspections of your Lifting Equipment, standard provided with the IMO Year Colour System.

Other colours available on request.

Your certificates are available to you online, 24/7.

(Non-) Destructive Testing

The in house testbed at our Workshop location is certified by NMI.

We carry out Destructive and Non-Destructive test according to our clients’ needs.

For Non-Destructive testing options of Steel Wire Ropes by means of Magnetic Reflux Testing we have several MRT kits

Annual Inspections of your Towing Gear, standard provided with the IMO Year Colour System.

Other colours available on request.

Our inspectors can thoroughly examine your fall protection equipment.

Contact our office to determine which option is most efficiënt for your scope and we will provide you with a quotation.

Our Riggers can handle your scope, wether it is a small lift or jacket.

Standard or special loads, our lashing teams have experience with a wide variety of different loads.

To complement our own works we can also arrange the erecting of scaffolding for the project.

Providing our One Stop Shop philosophy allows you to focus on the project controll and progress, without having to spend time on finding extra sub-contractors for single tasks.

- Lifeboats

- Rescueboats

- Davits

- Release Gear

- Fire Fighting equipment

- Lifts

- Cranes